The Things that I'm Willing to do for this FYDP

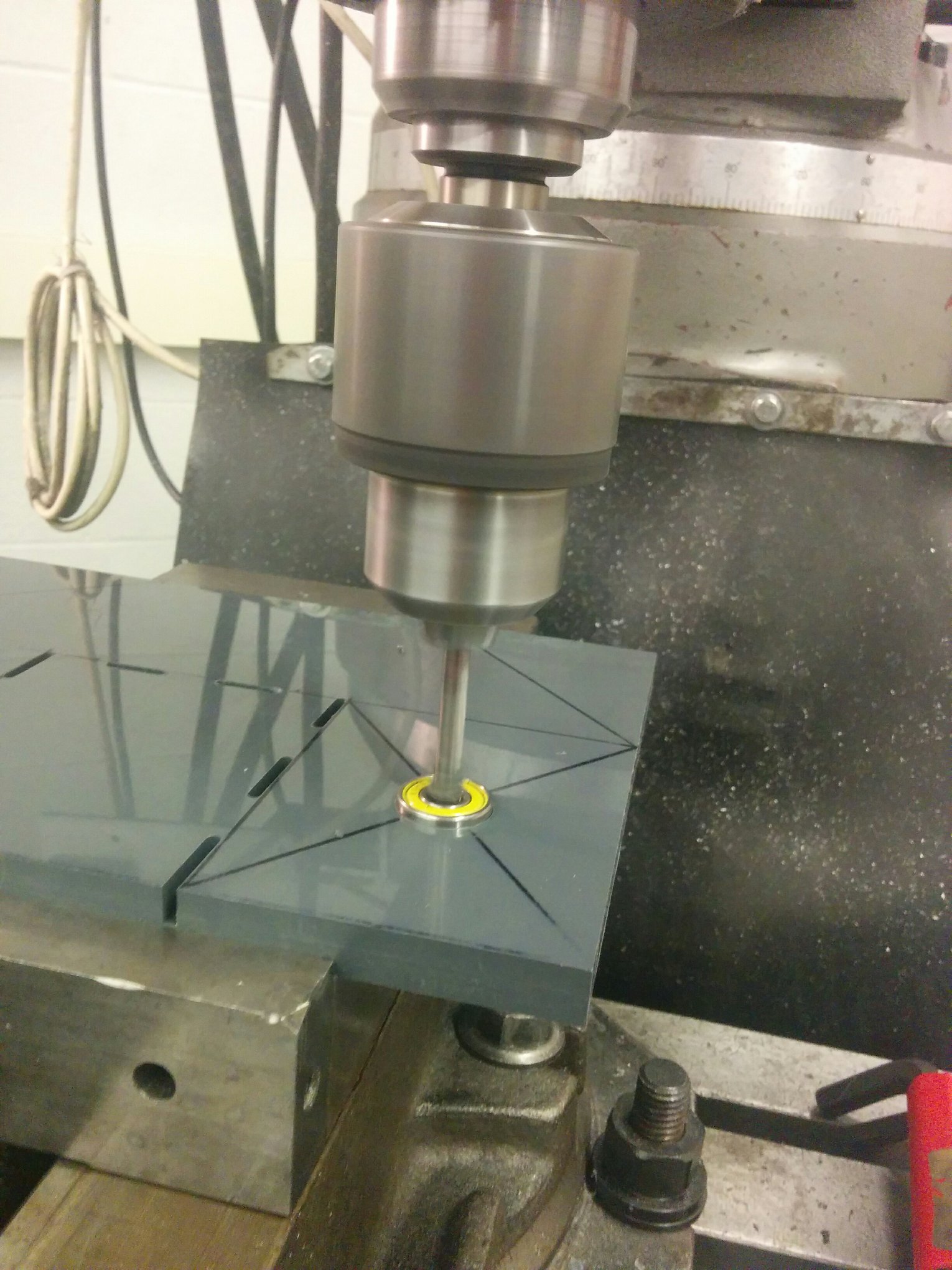

This week was mostly a machining week. The most exciting things I had to do is use an over foot long drill bit in the mill to make holes from the outside of the part so that they could be located inside the elevator shaft. I also milled the 3D printed Pi Platform. Don't do this! It melts the plastic and comes out really rough but it reduced the width as I wanted. The drilling of the 1.5mm acrylic was even more questionable but I had forgotten holes for the clear door hinges and wanted to hand the assembled part off to the electrical and firmware wizards of the team to tinker with.

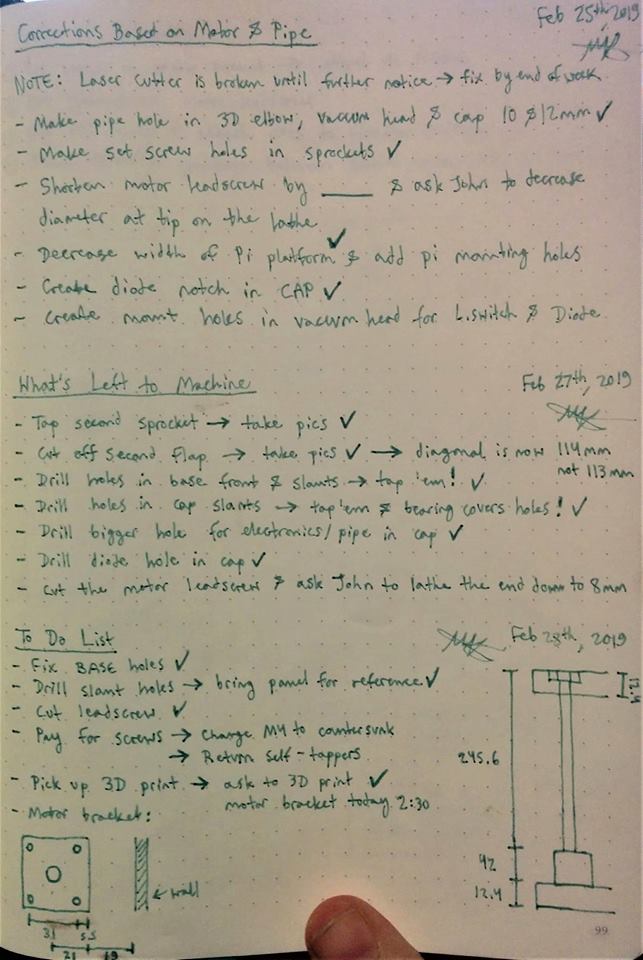

During this week I also managed to machine holes for the Base bearing and press-fit it and mill slots for the lasercut elevator shaft walls. This completed the Base part!

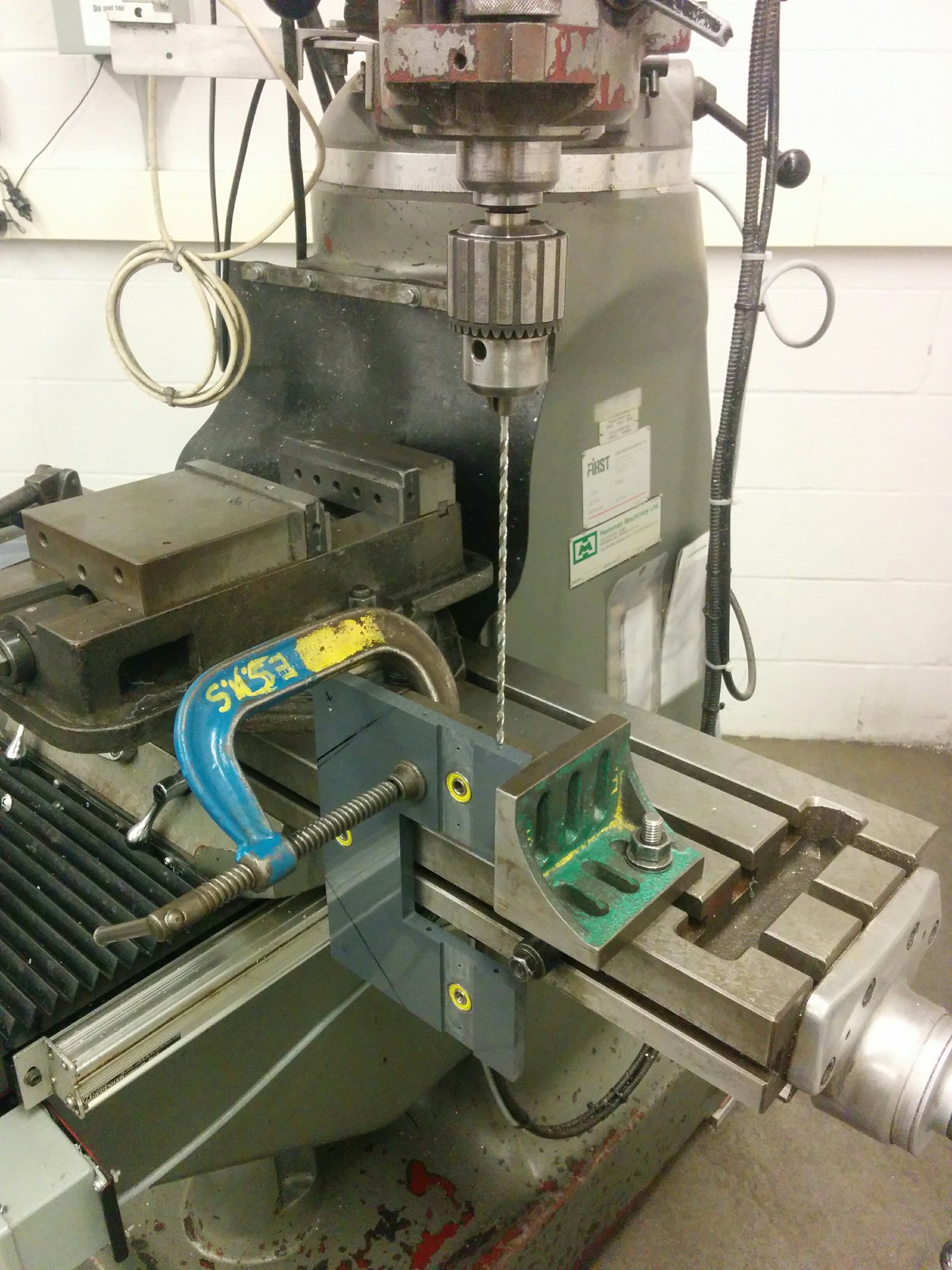

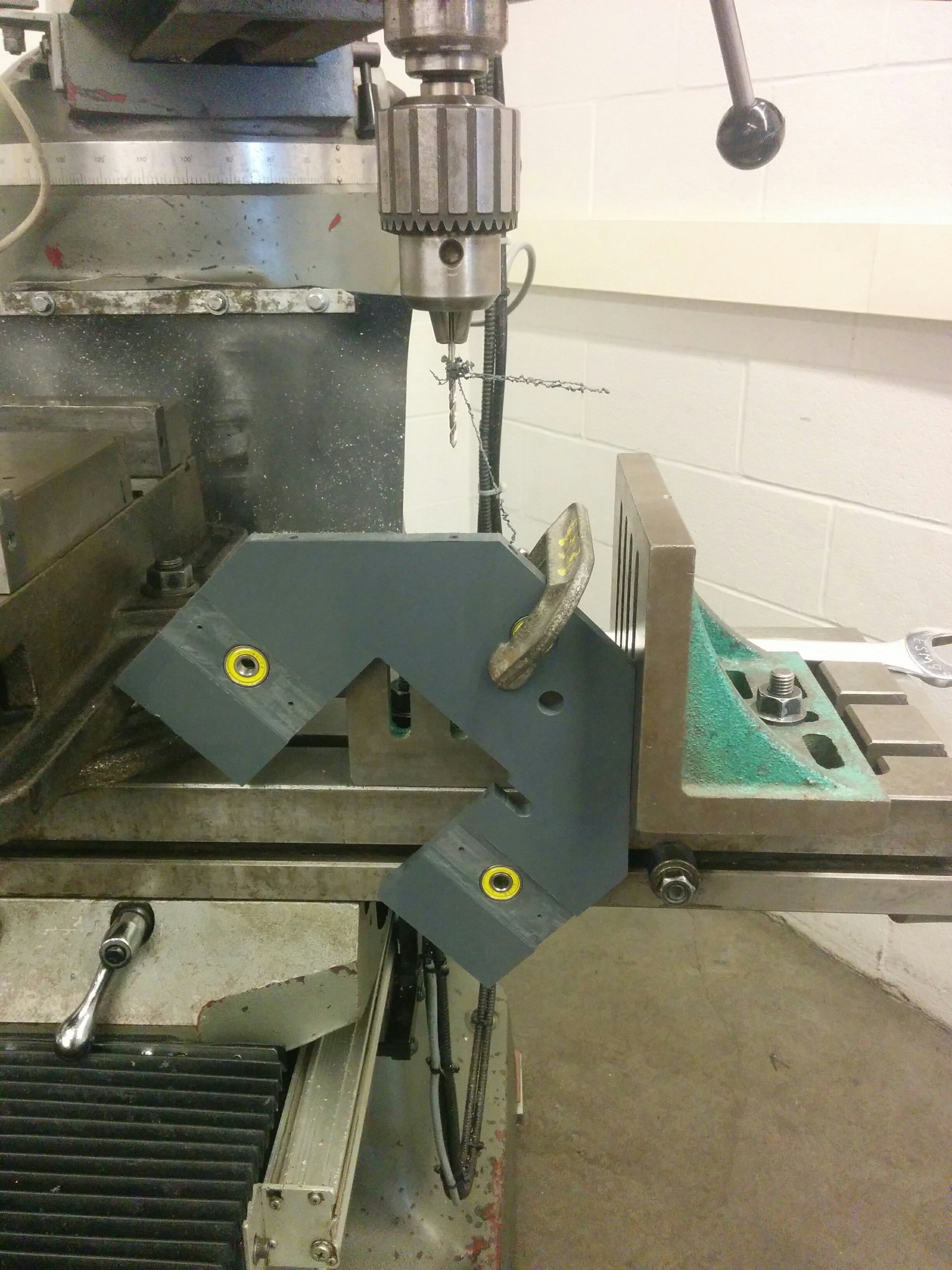

Final machining included cutting off the edges, putting screw holes in the edges (led to some exciting vice placement), and tapping those holes. Next, the sprockets we had just received were drilled and tapped so that set screws could be placed and the elevator motor leadscrew was shortened. Lastly, the piano hinges for the doors were cut down to size.

Below are pictures of that process happening!